Welcome to RDN Manufacturing Co., Inc. Our 40,000 square foot facility includes offices, an extrusion laboratory, an assembly area and the machine shop.

RDN Manufacturing is a dedicated manufacturer of high quality post-extrusion equipment with a focus on optimizing extrusion productivity. Our full line of downstream equipment with innovative features that:

- Cut costs

- Decrease downtime

- Solve problems

- And Increase your profits!

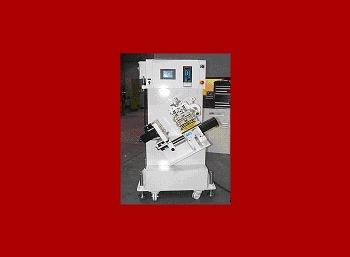

Our machines are designed to make maintenance go as quickly and easily as possible. They are engineered to provide fast access to operating mechanisms, minimizing maintenance downtime. For example, with just four quarter turns of a flat-blade screwdriver you have complete access to our new INTELLICUT® Servo Cutter. And you can change its cutting blade in five seconds or less!

RDN’s extrusion laboratory is another unique advantage for our customers. This is where testing is conducted on processes and equipment. It’s an ideal place for training and process experimentation and we invite our customers to make use of it.

Since 1967 we have positioned ourselves to become a Global leader in production and service for the plastics industry. We are committed to serving our customer’s needs for today and the future. For information on how we can serve you, please Call or Email us. We look forward to hearing from you.

Post Extrusion Plastics Equipment Innovations

RDN Manufacturing , the global leader in post extrusion plastics equipment, develops hardware and software innovations to enhance extrusion productivity.

Software advancements bring corrugation cut-off to new heights

RDN Manufacturing’s programming and R & D teams have taken their already revolutionary ‘Corrugated Tube Cuff-Cutting System’ to the next level. In order to keep up with advances in technology, RDN has designed firmware specifically to handle the high-speed requirements of a servo access control card.

Simply put, the system employs a photo-eye for speed-of-light accuracy in cuff detection. The operator enters a preset value based on length – not time measurements, via a user friendly Touchscreen. The system’s photo-eye in turn signals the RDN controller using a high-resolution encoder to position the cut(s).

First introduced in 2001, industries such as Automotive, Medical and Small Appliance Manufacturers have realized and appreciated the beauty of the precision cuts offered by the cost-effective CTCCS. Now, those cuts are more accurate and faster than ever, with a simpler operator interface. This option is available on all RDN INTELLICUT® Servo Cutters; a Puller/Cutter is recommended for optimal results.

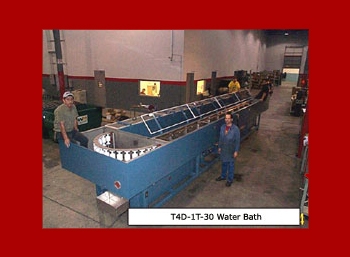

150′ Water Bath In One-Fifth The Space

Our customer came to us looking for the longest Water Bath possible with the smallest footprint possible. For comparison, the 1st photo is a standard 10′ long Water Bath that can process up to a 3″ OD tube or profile. But our Customer needed more… much more!

Here’s what we came up with for them. The 2nd photo is a 30′ long “Turn-Around” Water Bath. The product passes through a total of 5 times, providing 150′ of cooling in one fifth the space! The customer was up and running in no time – and still had room to move around.

Turning Gravity Into An Asset

We feel it is always much easier to “go with the flow.” So when our customers come to us with their problem project, our engineers set out to solve it. By thinking “outside the box” we turned gravity – which can be one of the greatest challenges an extruder faces – into a total asset.

Creative thinking is one of our strongest assets!

RDN is committed to making your productivity possible.