RDN Manufacturing Introduces New Servo-Controlled Roll Winder for Flexible Pipe, Tube and Filament Applications for the Automotive and Medical Industries.

Bloomingdale, IL – Aug 12, 2019 – RDN Manufacturing has introduced a new servo-controlled roll winder for flexible pipe, tube and filament applications for the automotive and medical industries. With a small footprint, easy set-up and familiar easy to use interface operators will be able to produce near perfect level rolls day in and day out without sacrificing performance, space, time, and most important your money.

The new winder produces a near perfect, level roll and features an easy-to-use interface that simplifies setup. The made to order winders have a footprint of 30 inches by 30 inches and can handle flexible pipe, tube, and filament made at speeds of up to 250 feet per minute. To begin, operators enter the outer diameter specs of the tube they plan to wind and an estimate of the line speed. Once operations begin, the winder can accommodate any line speed that’s with 25 percent of the estimate.

- New servo-controlled, roll winder for all flexible material. Perfect for 3-D filament.

- Suited for Automotive and medical industries

- Made to order

- Small footprint

- Line speeds of up to 250ft per min

- Easy access machine housing

- Operator can easily input multiple variables; line speed, core diameter, tubing (pitch) diameter

- Core width, and flange delays, etc.

- Simple operator inputs

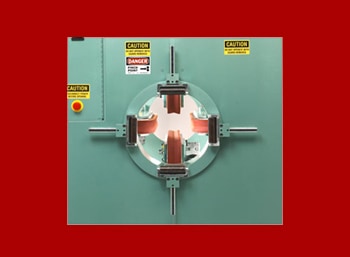

The Model 440 Four-Belt Puller from RDN Manufacturing Co., Inc. is designed and built to deliver a high level of accuracy and long-term dependability in heavy walled profile and pipe applications. Able to operate using either two or four belts, RDN’s Model 440 can accommodate a wide variety of tubing and pipe ranging from 3/8″ to 12″ in diameter.

The Model 440 features a 3HP (optional 5HP) AC Flux Vector Drive to ensure a steady, stable pulling force. The drive train consists of a four-speed transmission driving a gear reducer on each belt assembly with a continuous roller chain, allowing the puller generate a higher level of torque over a wider speed range.

The Model 440 utilizes continuous non-marking poly “V” groove 40/50 durometer solid neoprene traction belts. Since all belts close independently, the machine will operate in the following modes:

- As a four-belt puller

- As a two-belt vertical puller

- As a two-belt horizontal puller

As with all of RDN’s Heavy-Duty Belt Pullers, the Model 440 is built with heavy, welded steel and bolted construction. For safe operation, each machine features totally enclosed belt guards, an emergency stop button, and safety stickers.

Removable panels and hinged doors allow easy access for inspection and maintenance. Adjustable height jack screws and swivel casters are also provided.

Click here for more information on the Model 440 Belt Puller.