RDN Manufacturing is a leading manufacturer of post-extrusion equipment. We offer a selection of downstream equipment with a multitude of features that reduce costs, minimize downtime, and boost profitability.

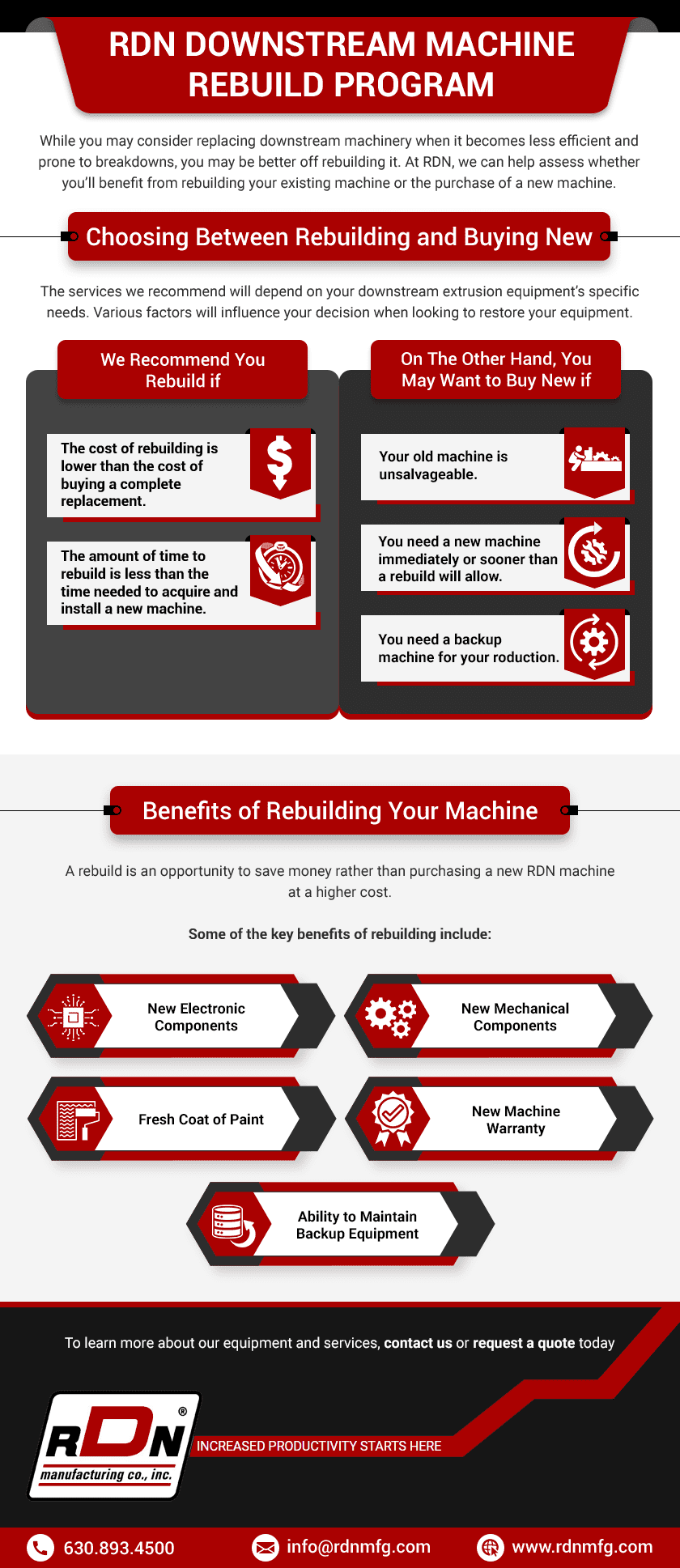

While you may consider replacing downstream machinery when it becomes less efficient and prone to breakdowns, you may be better off rebuilding it. At RDN, we can help assess whether you’ll benefit from rebuilding your existing machine or the purchase of a new machine.

Choosing Between Rebuilding and Buying New

The services we recommend will depend on your downstream extrusion equipment’s specific needs. Various factors will influence your decision when looking to restore your equipment.

We recommend you rebuild if:

- The cost of rebuilding is lower than the cost of buying a complete replacement

- The amount of time to rebuild is less than the time needed to acquire and install a new machine

On the other hand, you may want to buy new if:

- Your old machine is unsalvageable

- You need a new machine immediately or sooner than a rebuild will allow

- You need a backup machine for your production

Benefits of Rebuilding Your Machine:

In some cases, you may benefit from buying new. However, for our loyal RDN customers a rebuild is an opportunity to save money rather than purchasing a new RDN machine at a higher cost.

Some of the key benefits of rebuilding include:

- New Electronic Components

- New Mechanical Components

- Fresh coat of paint

- New machine warranty

Another benefit of a rebuild is the ability to maintain backup equipment. Many of our customers purchase new machines while old ones undergo a rebuild. This ensures they have a backup machine that keeps them capable of maintaining operations in the event of equipment failure.

Downstream Plastic Extrusion Equipment from RDN Manufacturing Co., Inc.

Whether you need a rebuild or new downstream extrusion equipment, RDN Manufacturing can give you what you need.

At RDN, we’re dedicated to increasing our customers’ productivity with top-quality equipment that meets their needs. Our capabilities include:

- Turnkey system development. We can provide every element required for custom extrusion machines, which helps make sure your development process is smooth from concept to installation.

- Product development & lab testing. After manufacturing or rebuilding your machine, we run it and test it to ensure it functions properly.

- Training and support. We offer training for your staff to help make sure your business can continue to maintain and operate machinery. We can also help with material changes, technical support, and product integration.

- Ease of machine maintenance. Our machines allow for easy maintenance to help minimize the risk of lengthy and costly downtime.

To learn more about our equipment and services, contact us or request a quote today. You can also take a look at our selection of extrusion equipment for more information.