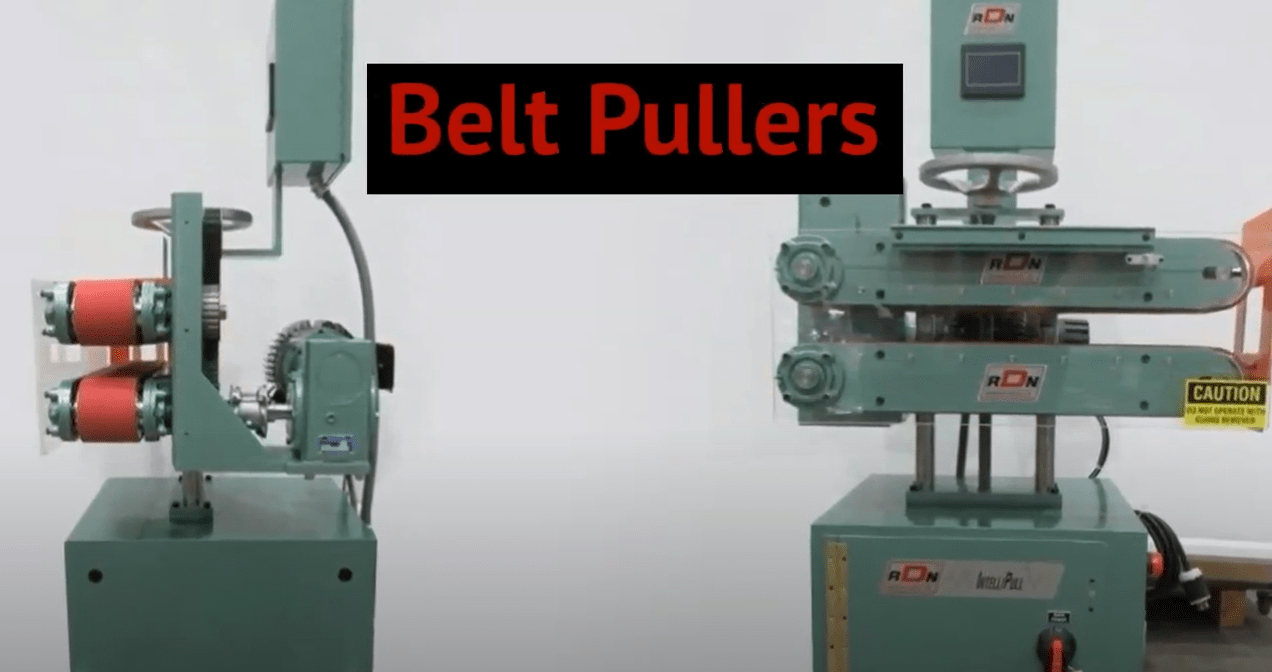

Belt pullers are used in extrusion systems to pull extruded components through sizing and cooling tanks and keep the extrusion process consistent. Belt pullers are composed of top and bottom belts, which are controlled by two separately powered traction drives to provide accurate speed and prevent slippage and relative motion between the two belts. Available in many varieties, belt pullers allow for speed regulation to meet the requirements of numerous applications.

Types of Belt Pullers

At RDN Manufacturing, we specialize in belt pullers for a wide range of volumes and workloads. Our three categories of belt pullers include:

Regular-Duty Belt Pullers

Our regular-duty belt pullers offer precise control through an AC vector drive and belts that adjust around a common centerline. The Poly “V” belts are non-marking, so they can be used to create clean, highly-regulated extrusions. These units are an excellent choice for small and medium size extrusions, and common applications include flexible tubing, medical tubing, and semi-rigid tubing.

Medium-Duty Belt Pullers

Our medium-duty units produce small and medium size extrusions. These easy to operate units feature conveniently mounted controls and non-marking Poly “V” belts to ensure clean contact with extrudate.

Heavy-Duty Belt Pullers

Our rugged heavy-duty units feature two or four belt pullers for optimal productivity. These machines feature totally enclosed belt guards to ensure operator safety, a four speed transmission to accommodate a variety of speed ranges, and pneumatic upper belt operation for ease of use. The non-marking, continuous Poly “V” groove traction belts ensure clean contact with extrudate while providing balanced loading for belt closing. Our heavy-duty belt pullers are ideal for high vacuum or long tooling applications as well as heavy walled profile and pipe extrusions.

What Are Belt Pullers?

Belt pullers pull extruded components through sizing and cooling tanks to create specific profiles. This step, which follows the initial extrusion process, ensures consistent product sizing and sets the product’s final dimensions to prevent deformations during subsequent cutting and finishing processes. By controlling speed regulation, belt pullers can accommodate the requirements for a wide range of applications, including garden hoses, medical tubes, irrigation piping, and more.

Belt Pullers from RDN Manufacturing

At RDN manufacturing, we specialize in creating high-quality hardware and belt puller units. We provide regular-duty, medium duty, and heavy-duty units to suit the various needs of our customers. Along with belt pullers, we also provide cutters, sizing and cooling tanks, saws, and other precision equipment for your extrusion operation. Contact us today to learn more about our machinery or browse through our catalog of available units.